Material Selection

Lip Material

Before selecting the right kind of sealing or lip material, it is extremely important to determine the type of environment, material selection and design recommendations in which the seal shall operate. See the below table.

Ratings

- Very Good

- Good for most application

- Fair can be used if other material available but otherwise not recommended

- Not recommended

| CODE | NR | SBR | EPDM | CR | NBR | ACM(PA) | SI | FPM |

|---|---|---|---|---|---|---|---|---|

| Properties\Compound | Natural Rubber | Styrene Butadiene Copolymer | Ethylene Propylene Rubber | Poly-chloroprene | Nitrile Rubber | Poly-acrylate | Silicone Rubber | Fluoro Rubber (Viton) |

| Tensile | 1 | 2 | 3 | 1 | 1 | 4 | 4 | 1 |

| Durometer | 30-100 | 40-100 | 30-80 | 40-90 | 30-100 | 40-90 | 30-90 | 55-90 |

| Rebound | 1 | 3 | 2 | 1 | 2 | 3 | 3 | 3 |

| Abrasion Resistance | 1 | 1 | 2 | 2 | 1 | 3 | 4 | 3 |

| Impact Strength | 1 | 1 | 2 | 1 | 2 | 4 | 4 | 3 |

| Gas Impermeability | 3 | 3 | 3 | 2 | 2 | 3 | 4 | 2 |

| Oxygen Resistance | 3 | 3 | 2 | 2 | 3 | 2 | 1 | 1 |

| Ozone Resistance | 4 | 4 | 1 | 2 | 4 | 2 | 1 | 1 |

| Weathering Resistance | 3 | 3 |

1 | 2 | 3 | 2 | 1 | 1 |

| Heat Resistance | 4 | 3 | 1 | 2 | 3 | 2 | 1 | 1 |

| Low Temperature | 2 | 3 | 2 | 3 | 3 | 4 | 1 | 2 |

| Water Resistance | 1 | 2 | 1 | 2 | 2 | 4 | 2 | 2 |

| Oil and Fuel Resistance | 4 | 4 | 4 | 2 | 1 | 1 | 3 | 1 |

| Animal, Vegetable Oil | 3 | 3 | 2 | 2 | 1 | 1 | 2 | 1 |

| Alcohol Resistance | 2 | 2 | 2 | 1 | 2 | 2 | 2 | 2 |

| Alkaline Resistance | 3 | 3 | 2 | 1 | 2 | 4 | 4 | 2 |

| Acid Resistance | 2 | 2 | 1 | 1 | 1 | 3 | 3 | 1 |

| Aliphatic Solvent | 4 | 4 | 4 | 2 | 1 | 1 | 4 | 1 |

| Aromatic Solvent | 4 | 4 | 4 | 2 | 1 | 1 | 4 | 1 |

| Oxygenated Solvent | 2 | 2 | 1 | 4 | 4 | 4 | 3 | 4 |

| CODE | NR | SBR | EPDM | CR | NBR | ACM(PA) | SI | FPM |

- * Other materials like: P.T.F.E (Teflon), Butyl, Vamac, Felt, and Leather are also available for seals and other molded products.

- * Please contact TCK for your specific applications and requirements.

Metal Case And Spring

The other major components of an oil seal are the metal case and garter spring.

| CASE | |||

| SAE. NO | AISI NO. | APPLICATION | COST |

|---|---|---|---|

| 1008~1010 | 1008~1010 | GENERAL | LOW |

| SAE 30304 | 304 | SPECIAL CORROSION RESISTANCE | HIGH |

The metal case generally is produced from carbon steel for general applications in oil or grease. For special applications when sealing sea water for corrosive fluids for gases, stainless steel can be applied at an increase in price. Other metal case like: Aluminum case, Brass case fare available for your specific applications and requirements.

| SPRING | |||

| SAE. NO | AISI NO. | APPLICATION | COST |

| 1070~1080 | 1070~1080 | GENERAL | LOW |

| 30304 | 304 | SPECIAL CORROSION RESISTANCE | HIGH |

| C5210R | C5210 | CORROSION & AGING RESISTANCE | HIGHER |

For the garter spring , piano wire is used for general applications. Wherre corrosion resistance or extreme heat resistance is required, stainless steel is available.

Shaft and Housing Recommendation(SHAFT)

- Shaft Speed- An important factor in seal selection.

- Temperature- For extreme temperatures, special compounds can be used.

- Pressure- Where pressure above nominal press-fit, special seals should be used or pressure against sealing lip relieved.

- Grinding-Rotating Shaft: plunge grinding is recommended.

- Reciprocating Shaft: center less grinding is acceptable.

- Shaft Hardness-Normally seals contact area of the shaft should be rockwell C 45 minimum

- Shaft to Bore Misalignment: Fixed misalignment of center of shaft with

- Bore center concentrates wear at one side of the seal which becomes more severe as speed increases.

- Shaft -Run-out ( eccentricity or shaft whip ) should keep to absolute minimum creates difficult sealing problem.

Shaft Design Recommendation

The other major components of an oil seal are the metal case and garter spring.

| SHAFT DIAMETER TOLERANCE | |

| up to 4.000 shaft | |

| 4.00 1 to 6.00 shaft | |

| 6.001 to 10.000 shaft | |

| Pressure Limit | |

| Shaft speed-FPM | Maximum Pressure-PSI |

| 0-1000 | 7 |

| 1001-2000 | 5 |

| 2001 and Higher | 3 |

| Eccentricity Limits | ||

| Speed Range | Max Misalignment | Max Shaft Run-out |

| 0-800RPM | 0.015 in ECC | 0.025 in TIR |

| 800-2200RPM | 0.010 in ECC | 0.020 in TIR |

| 2200-4200RPM | 0.010 in ECC | 0.015 in TIR |

Housing Bore:

The different material of bores is to be recommended using in rubber covered and metal O.D seals as followe: Robber covered O.D: steel and cast iron, soft alloy, aluminum alloy, plastic or nylon.

Metal O.D : steel and cast iron

*Bore Design Recommendation :

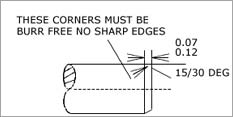

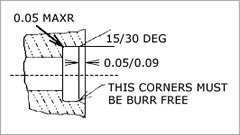

Bore Chamfer :

To assist installation of the seal, a bore chamfer is necessary. If without or improper chamfer will distort seal case and will require more assembly force craving is our recommendation of the chamfer.

*Bore Dimensional Tolerances

To assure proper fit of oil seals, the dimensions of bore are recommended within the tolerances listed below. TCK seals are made to satisfy tight size specifications. Seals O.D are normally. .004" to .010" (.10mm to .25mm) larger than the seal bore size.

Bore Chamfer in inch sizes

BORE DIAMETER IN METRIC SIZES

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Seal O.DThe average of minimum three measurements to be taken at equally spaced positions

- Eccentricity-The maximum variance between any of the readings used in determining seal O.D.

Rotary Shaft Seals

There are hundreds of different cross sectional shapes available today in rotary shaft seals. Although TCK has a variety of shapes tooled and availabe. We teach and use a tired and true method of evaluating the application data, step-by-step answering critical questions about what the seal must do, the parameters and conditions under which it must live and arriving at a generic definition of the seal required. Then we search the available shapes and tooled sizes to see if the right one exits. If it doesn't, we prepare to develop it for our customer.

Teflon Seals and Engineered Components

TCK is equipped to provide high volume, low cost Tteflon and Teflon blend components of consistent quality as well as short run and prototype quantities. Various production methods are available depending upon component geomerty, quantity, and material requirements. TCK has extensive experience in the design and fabrication of Teflon compounds used as seals ( valve seals, lip seals , face seals, shaft seal elements). We have an ever-increasing menu of Teflon blends available to either machine or mold any sha p e components you may need.